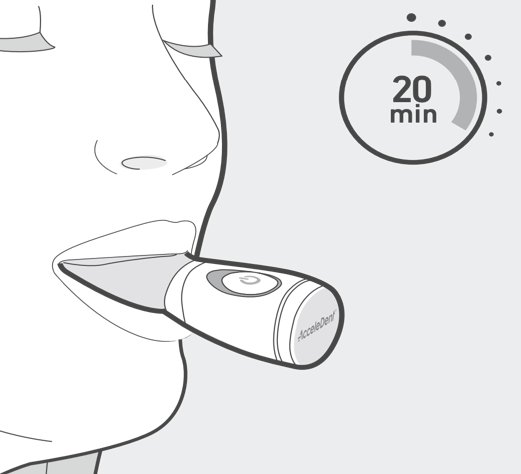

The AcceleDent Optima is a daily-use device, and had to be intuitive, comfortable, and user-friendly. Eclipse examined every aspect of the user experience and identified key areas to improve usability over their previous version of the device. For example, users had issues with the previous generation device getting in the way when completing some common tasks.

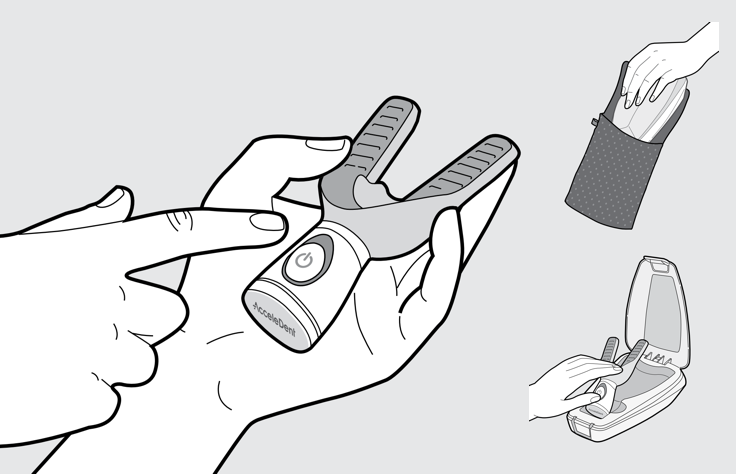

We made the product and its charging/storage station more compact, easier to see status indicators, and enabled one-handed operation.

We also developed a mobile application, and web interface for the system to encourage users to track their progress with the device via the app.

Finally we designed a display stand that would demonstrate the product in orthodontist offices.

Thanks to focus groups with current and prospective users, we knew right from the start that the Optima had to be as small and sleek looking as possible if it was to be used by the target market. We held discussions in five cities across the country to get as much input as possible before we even started sketching.

We also found that consumers needed to be able to travel with their orthodontic devices such as this, so a carry case was an important addition. The carry case could also be used as a charging base thanks to an inductive charger built into it.

Designing something this small, with a control board, motor, battery, inductive charger and indicator lamps is always a challenge. Adding in the requirements that it needs go into a users mouth, be waterproof and be able to be dropped without breaking makes it even more complicated. Fortunately we were working with a great team at Acceledent, and could rapidly iterate many ideas for how we could fit everything into a small package.

To get a good transmission of the vibrations into the mouthpiece we decided to overmold the mouthpiece onto the case. This would also make it easier to clean everything before and after use, as there would be no seam to get dirty. All the internal components were fitted into a very compact chassis that was a press fit into the case, and then a clear ring and the end cap were ultrasonically welded to seal everything up.

The carry case was designed to be sleek, but also have a definite latch to hold it closed while traveling. Electronics for charging were in the base, and the assembly was held together with heat stakes. We designed the case with oversized features where the upper part overlaps the lower to help keep water away from the electronics.

Significant in-house testing was done throughout the design and development process, with submerging the assembled mouthpiece, and drip tests on the charging case, as well as many drop tests onto wood surfaces documented with a high speed camera, followed by more submerging to test the welds were not compromised.